Zebra Aurora Vision Software Success Stories

Zebra Technologies stands at the forefront of computer vision software. The

Aurora Vision software empowers users to effortlessly build their own image processing programs for automation projects. Users such as computer vision integrators find a swift and seamless path to solving automation challenges. This image processing software of Aurora Vision creates a robust graphical environment for machine vision engineers, giving them the tools for applications such as quality inspection and industrial automation.

Aurora Vision software is based on a dataflow-based approach, including a variety of pre-built image analysis filters. Tailor-made for professionals, it simplifies the creation of common applications and streamlines the development of customized projects. This adaptability makes it a go-to tool for computer vision engineers addressing diverse quality inspection and automation needs in the industrial sector.

This Zebra Aurora software webpage showcases a range of computer vision software packages for image processing including:

- Aurora Vision Studio: A powerhouse of simplicity, offering a graphical low-level programming environment for quick development and easy customization by machine vision engineers.

- Aurora Vision Library: Ready-to-use features for C++ and .NET programming, giving you the freedom to develop your own software for even the most complex applications.

- Aurora Vision Deep Learning: This Aurora Vision software add-on allows you to select images, mark defects/labels, and train the software for your specific application. Dive deep into optical character recognition with the pre-trained Deep Learning OCR tool. This tool is perfect for deciphering complicated, damaged, or blurred characters. It's the ultimate solution for overcoming visual challenges in character recognition.

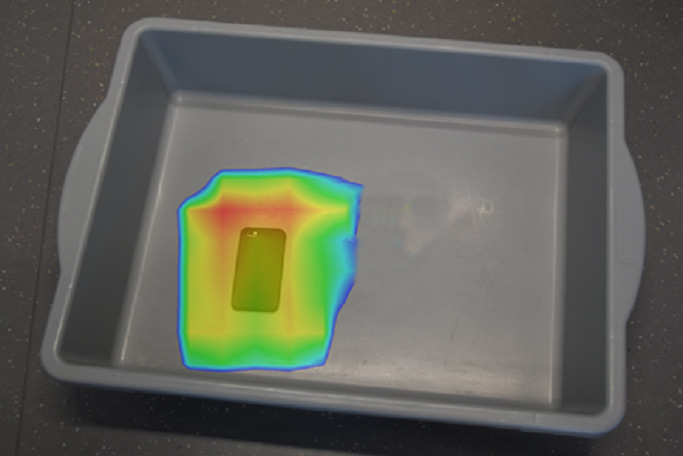

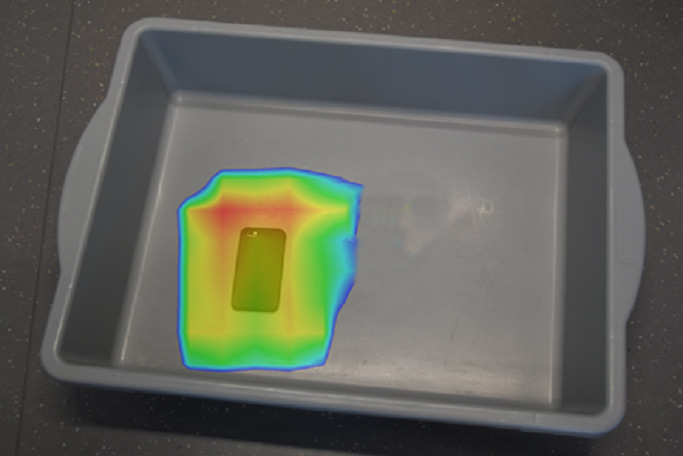

Airport trays verification

The Aurora Vision software of Zebra Technologies includes advanced deep learning add-on packages. For airport security tray verification advanced object detection algorithms are available. More specifically, the software empowers users to create own algorithms to their unique needs, as exemplified by the Vienna University's pioneering work. In this example application, the university developed an algorithm within Aurora Vision software to discern and categorize items within airport security trays.

Vienna University's algorithm, meticulously trained on a dataset comprising 150 images including three different classes, showcases the software's adaptability. The three categories include an empty tray, a tray containing an object inadvertently left behind, and a tray requiring attention due to spillage of liquids. This tailored approach ensures a comprehensive assessment of tray contents, which improves security measures and operational efficiency at airport checkpoints.

The utilization of machine vision cameras in combination with Zebra Aurora Vision is paramount to the success of this innovative verification system. The software seamlessly integrates with machine vision cameras, enabling real-time analysis of tray contents. The synergy between the machine vision camera and Aurora Vision's deep learning capabilities empowers the system to not only identify objects but also provide insightful visualizations through heatmaps. The heatmap generated by the vision algorithm serves as a visual guide. Zebra Aurora Vision software, combined with machine vision cameras, takes airport tray control to the next level of precision and efficiency in the context of security protocols. Explore

the details of this success story via this link.

Diameter Inspection

For this vision project, a few engineers have used the Zebra Aurora Vision software to develop an innovative application dedicated to diameter dimension inspection of tempered steel rings. Inspection of the roundness and inner diameter dimensions of steel rings. By harnessing the power of machine vision cameras, this advanced system provides highly accurate assessment. Thus allowing the engineers to examine these critical components to an impressive tolerance of up to +/- 0.1 mm.

The Zebra Aurora Vision software plays a pivotal role in this success story, providing a robust platform for diameter inspection that goes beyond conventional limits. Its adaptive algorithms, seamlessly integrated with machine vision cameras, facilitate real-time measurements and analysis. The Aurora Vision software ensures that the inner diameter of the steel rings meets stringent quality standards. This breakthrough not only signifies a significant advancement in industrial inspection processes but also underscores the transformative impact of Aurora Vision software in achieving unparalleled accuracy and efficiency in dimensional assessments. Explore

the details of this success story via this link.

PCB Positioning

The Zebra Aurora Vision software, particularly the advanced Zebra Aurora Vision Studio, is taking a technological step forward and has emerged as a game-changer in the field of PCB positioning. In this application, the Aurora Vision software is used combined with a 5MP monochrome camera such as our

MER2-503-36U3M camera. This combination led to accurate determination of PCB positioning with an impressive measurement accuracy of up to 0.05mm.

The use of Aurora Vision software adds a new dimension to the inspection process, allowing PCB positioning to be accurately examined. The versatility of the software is illustrated by its compatibility with flexible macro filters, allowing customised adjustments to meet specific application requirements. What sets this success story apart is the seamless integration capability, which allows quick export of DLL files. This feature not only streamlines the integration process, but also gives users the flexibility to seamlessly incorporate the solution into their own operating software. Read more

about this success story via this link.

Filter

Filter